Manufacturing Facilities - Kirloskar Ferrous

The art of engineering transformation begins with a world class Infrastructure.

We have honed our expertise through the years and are invested in strengthening our manufacturing capabilities. This has allowed us to drive the production of complex and critical engine castings in high volumes. Our focus on quality and performance ensures that every casting we produce meets the requirements of discerning customers.

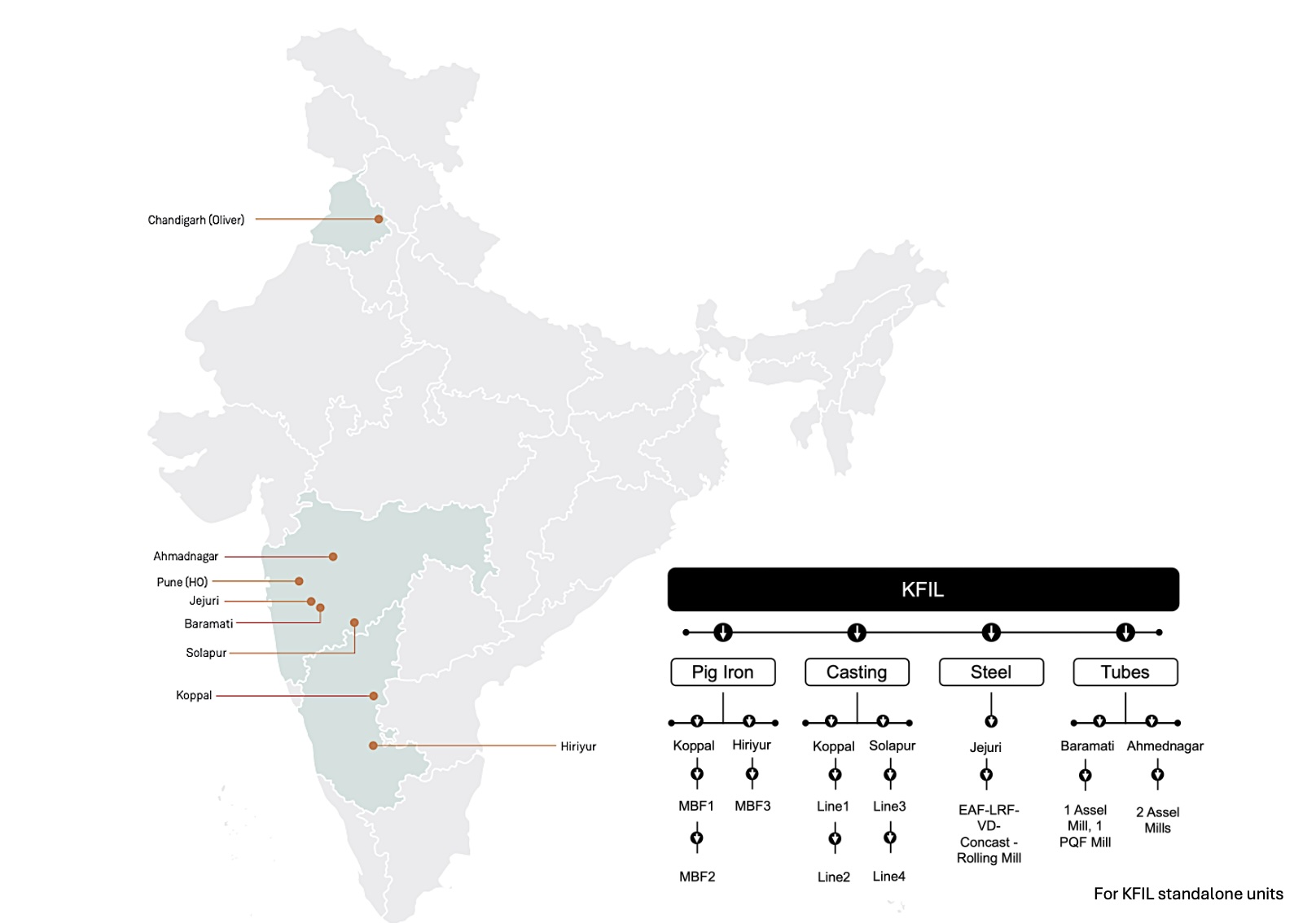

Our Plant Locations and KFIL Standalone Manufacturing Footprint