Hydraulic Cylinders - I - Kirloskar Ferrous

Hydraulic Cylinders - Type I

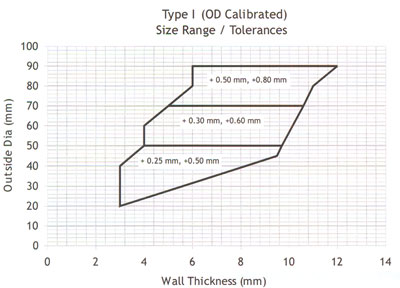

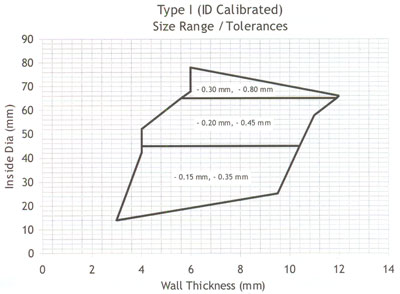

These are precision tubes produced through a process of cold-pilgering wherein the tubes are heavily cold worked between moving dies (up to 70% cross sectional reduction) resulting in a very even surface finish and extremely tight dimensional tolerances. These tubes can be directly honed to obtain the final finish and dimension required on the bore surface. Consequently, these tubes are economically well suited for the manufacture of large volumes of standardized cylinders.

Eccentricity

| Outside Diameter | Eccentricity | ||

| 100 mm | 0.05 | Eccentricity**= | (WT max - WT min) |

| 100 to 140 mm | 0.07 | (WT max + WT min) | |

** Where WT max and Wt min are measured on the same cross-section

Straightness

Straightness is guaranteed to be better than or equal to 1 mm per 1000 mm.

Ovality

Ovality is guaranteed to be contained within the overall tolerances on the diameter.